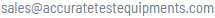

Typical Configuration :

- NI DAQ Hardware – typically 250 Ks/S aggregate (High Sampling on Request for High End applications)

- Chassis for Sensor Connection – with 4 BNC Connectors for Voltage Inputs and 9 Pin D-Connector for Encoder Input

- A 360 PPR encoder for 1 Degree Crank-Angle Resolution (0.5 and 0.2 deg CA resolution available with Higher Sampling NI Cards on request)

- Kistler 6613 CQ09 Sensors with Inline amplifiers with suitable Power Supply for the same

We are Manufacturer, Supplier, Exporter of Data Acquisition Systems and our setup is situated at Kolhapur, Maharashtra, India.

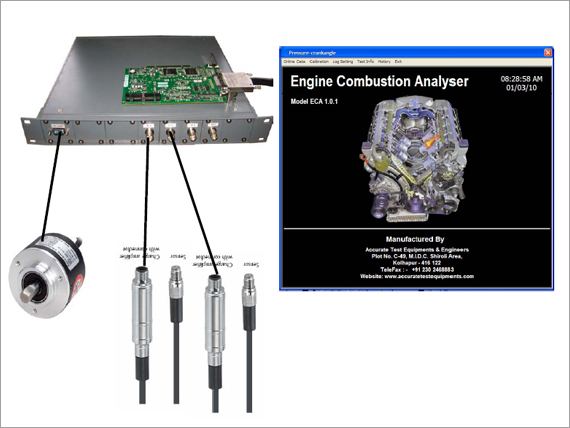

Facilities Provided in ECA Software :

- Configuration of Hardware with software

- Engine Geometry Settings

- Measurement settings such as Polytropic Coefficient, Pressure Curve Correction etc

- Calibration Settings for Analogue Channels.

- Online Display of Pressure v/s Crank-angle, Pressure v/s Volume, Instantaneous and Integrated Heat Release data, Pressure derivative signal, RPM variation

- Online Calculations for IMEP, IHP

- Bar graphs for instantaneous IMEP and IHP for observing cycle to cycle variations

- Facility of Saving Cycle Data.

- Facility of Report Generation

- Facility of Combustion Data Export to Microsoft EXCEL

- User can Zoom into Specific Portion of the Graphs during online data acquisition as well as in History mode (offline)